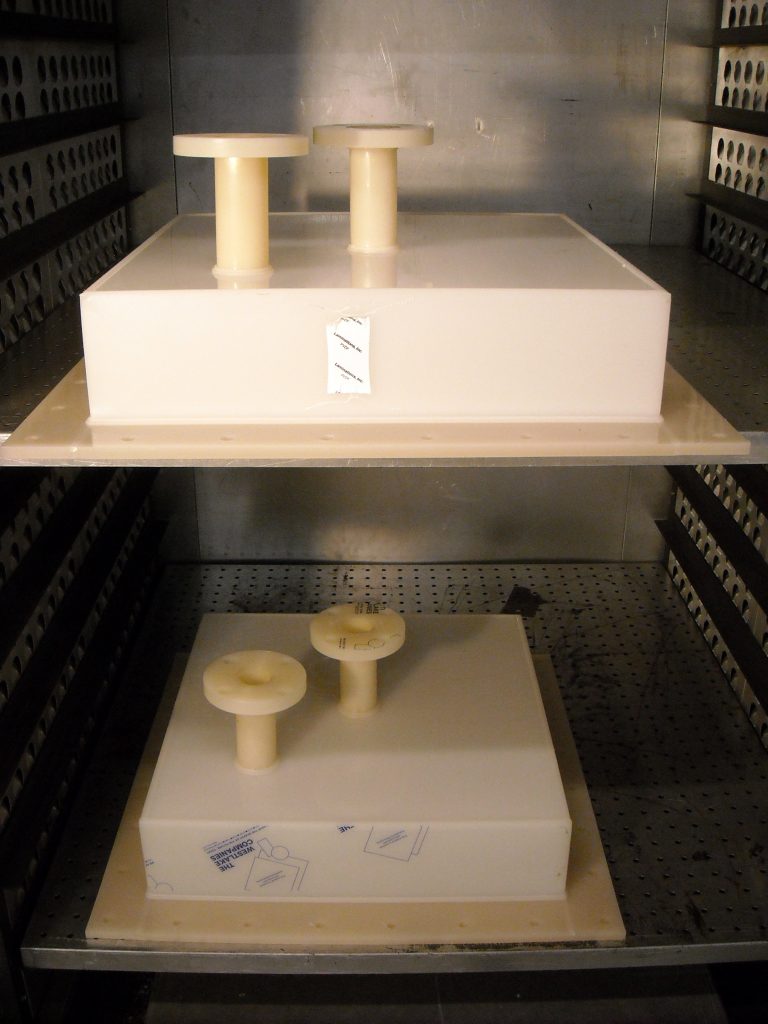

At Miller Plastics, we’re your single source for Annealing of plastic products and components. Our machined products are annealed to ensure dimensional stability and strong, stress-free parts. It also enables use in higher temperature environments with minimal deflection.

Our annealing services are available to you in our high tech programmable ovens.

Additional Value-Added Services Include:

- Prototyping

- Thermoforming

- Annealing

- Assembly

- Stocking Programs

- Welding

- Pipe Bending

- Machining

Annealing – We Relieve Your Stress

Annealing is the process of relieving stresses built up in the materials during processing. Annealing plastics can increase the longevity of your machined plastic parts and components, saving you time and money!

At Miller Plastics, we carefully analyze each part to determine the best annealing method for your application requirements.

We understand the success of your plastic parts depends on the success of our processes.

Advantages

- Eliminates Crazing

- Improves material rigidity

- Prevents stress fractures

- Increases chemical-resistance

- Provides ability to sustain high temperatures without deflection

Thermoforming

Thermoforming is the process of heating and forming many of today’s modern plastic materials into highly useful and cost effective parts such as control panels, displays and many others.

The automated process achieves faster cycle times than in other forming processes.

Only thermoplastic sheet can be processed by this method.

The plastic sheet is softened at the heating station. It then indexes to the forming station where the mold tools are located. The forming of the sheet is by a combination of air pressure and vacuum.

Many thermoplastics can be thermoformed; they include Polystyrene, Kydex®, Apet, Lexan®, PVC, and more.

Some of the Materials We Work With Include:

Inspection Capabilities:

- Full 3D CMM (Coordinate Measuring Machine)

- Ability to Scan and Completely Reverse-Engineer Even Your Most Complex Parts

- Complete Digitizing Capability With Laser-Scanner

- CMM Can Completely Scan a Part or Gear and Produce a Useful Model

- Ability to Scan and Completely Compare Your Parts to CAD Model