Design & Fabrication of Custom Solutions for Process Applications.

As the leading design and fabrication manufacturer of custom fabrications for process application, Miller Plastic Products can provide custom solutions to meet specifications that are unique to your application and/or environment.

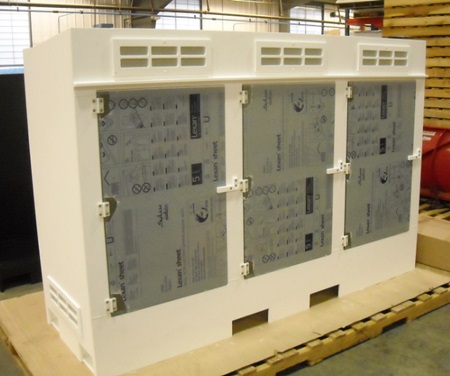

The dosing skids, pump stands and process cabinets that we design and fabricate are manufactured with high strength inert materials, making them ideal for highly corrosive environments.

At Miller Plastic Products, our certified welders and expert CNC machinists can create most any configuration you desire.

We have open-style skids, frames, stands with back, and fully-enclosed cabinets, all of which are available in a variety of materials.

All edges and components are CNC cut, nothing leaves our shop with saw cut edges, Burrs, or sharp edges.

Typical Features Include:

- Pump Risers

- Pipe Stand-Offs

- Custom pipe work

- Valve Mounts

- Supplemental Tanks & Hoppers

- Fume Ducting

- Integral Secondary Containment

- Reinforcement for Harsh Handling

- Chemical-Resistant Materials

- Handles

- Forklift Openings

If your application and/or corrosive environment requires a specialized dosing skid, pump stand or process cabinet, turn to the experts at Miller Plastic Products. We work with you to ensure the very best solution for your needs.

Every component is CNC cut for accuracy, repeatability and smooth furniture quality finish. Nothing leaves our shop with saw cut edges, Burrs, or sharp edges. When applicable, individual parts are indexed for automatic registration to ensure strength, rigidity and correct alignment.

Our plastic welds are the best in the industry, and comply with the more strict German DVS welding standards. They are smooth and easy to clean.