At Miller Plastics, we take pride in our state-of-the-art CNC equipment which allows us to deliver the highest quality plastic components that are machined to our client’s standards.

Our team of expert machinists are skilled at creating parts that fit tight tolerances and are consistently produced over high volumes.

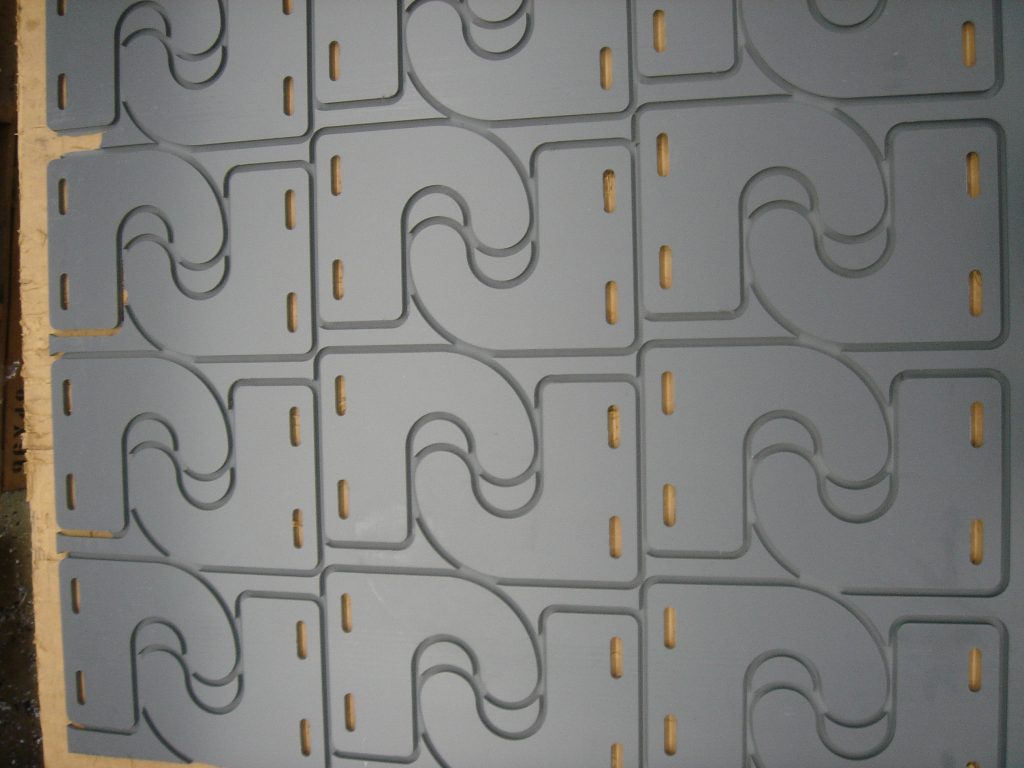

Our CNC department is cost-effective and no job is too big or too small. CNC plastic routers ensure high-speed automated routing of all types of plastics, and we can cut plastics to meet any design requirements – from simple cuts to complex shapes, dual head and single head machines cut nested parts very efficiently.

Our plastic machining capabilities and benefits include:

- Most Materials in Stock

- State-of-the-Art Computerized Machinery

- Produce Parts from All Types of Plastics

- Many Products Annealed for Maximum Strength

- Custom Parts Made from Samples, Prints, or Sketches

- Complete CNC & Conventional Machining Facilities

- Post Machining Inspection with 100% Inspection Reports Available

- Precision Plastic Components, Custom-Machined to Your Specifications

We offer many different types of CNC machining processes including:

- 3-Dimensional Machining

- Live-Tooling on Lathes

- 5-Axis Lathes & Mills

- Large-Capacity Machining for Larger Parts

- Solid-Model Feature-Recognition Programming (using solidworks)

In addition, our machining department is equipped with a wide range of capabilities including CAD design, CAM programming and 3D programing.

Our CNC Routers can process a wide range of components from micro milling to 6′ x 10′ parts.

Equipped with dual spindles, Miller Plastics’ CNC machines can complete many components with fewer setups and more efficient cycle times than traditional single head production methods. The best and most consistent components in precision plastic routing are produced at Miller Plastics’ facility in Burgettstown, PA, near Pittsburgh.

Some of the Materials We Work With Include:

Inspection Capabilities:

- Full 3D CMM (Coordinate Measuring Machine)

- Ability to Scan and Completely Reverse-Engineer Even Your Most Complex Parts

- Complete Digitizing Capability With Laser-Scanner

- CMM Can Completely Scan a Part or Gear and Produce a Useful Model

- Ability to Scan and Completely Compare Your Parts to CAD Model