As One of the Top Polypropylene Pipe Fabricators in the USA, We Provide Standard & Custom Solutions through Design, Engineering, Fabrication & Machining to Suit Your Specific Application and Environmental Needs.

As one of the top polypropylene pipe fabricators in the USA, Miller Plastic Products provides standard and custom solutions to suit your specific application and environmental needs.

We actively work with you to ensure requirements are met or exceeded for:

- Thermal Conductivity

- Thermal Expansion

- UV Resistance

- Longevity of Performance

- Chemical Resistance

- Thickness

- Size

- Diameter

- Structural Integrity

- Any other polypropylene pipe properties you require

Some of the Materials We Work With Include:

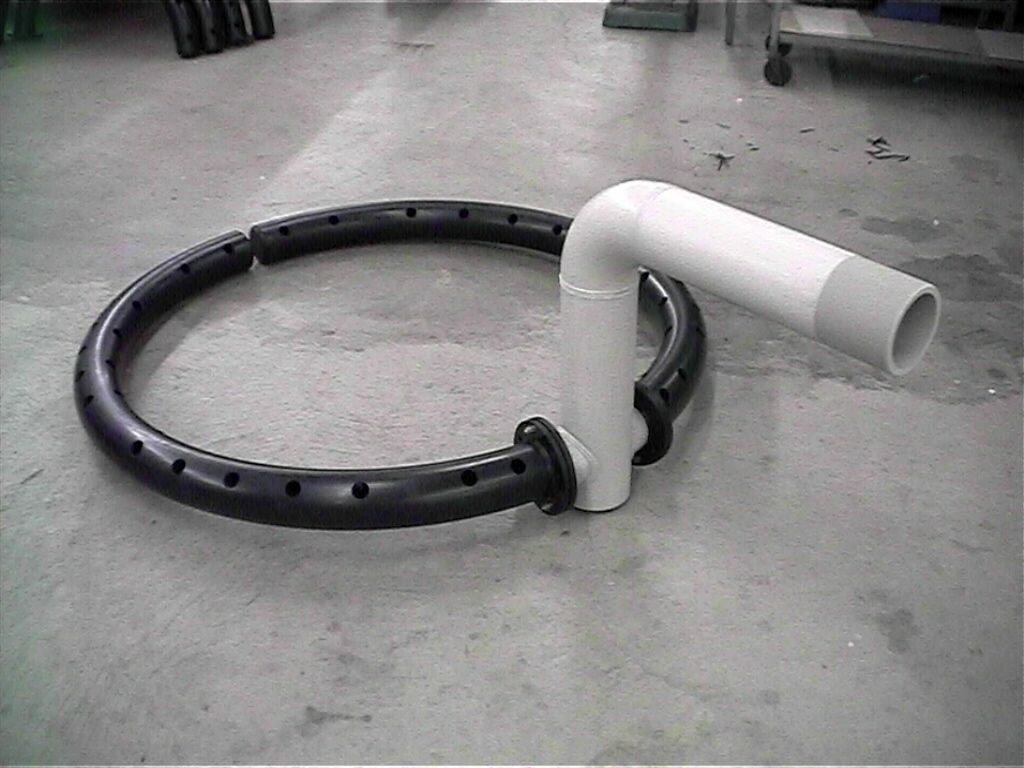

Our polypropylene pipes, valves and fittings are widely used throughout the industrial processing markets

We provide polypropylene piping systems for drainage, natural gas, ventilation and more.

Polypropylene piping systems are desired for their lightweight properties, abrasion resistance, high impact strength and reliability in heat fusion welding, as well as its thermal and electrical insulation properties.

Polypropylene piping systems are also revered for their superior chemical resistance, which makes them resistant to a large amount of organic solvents, including acids, alkalis and salts.

Polypropylene pipe maximum temperature for working use is 90ºC (194ºF); however, it can endure short term use up to 110ºC (230ºF). Polypropylene piping systems can be assembled by means of heat fusion welding, butt fusion, or through electrofusion fittings, socked-ended fittings or threaded fittings.